Proper maintenance of blister pack recycling equipment, also known as aluminum–plastic separators, is essential for maintaining stable separation purity, safe operation, and long-term return on investment. Unlike conventional packaging machinery, recycling systems operate under extreme abrasion, fine dust conditions, and high-voltage electrostatic fields, especially when processing pharmaceutical aluminum–plastic composite materials. Without a structured preventive maintenance strategy, issues such as reduced separation efficiency, abnormal vibration, dust leakage, and accelerated wear can quickly impact productivity. A well-executed maintenance program can reduce annual operating costs by 15–30%, while significantly extending equipment service life.

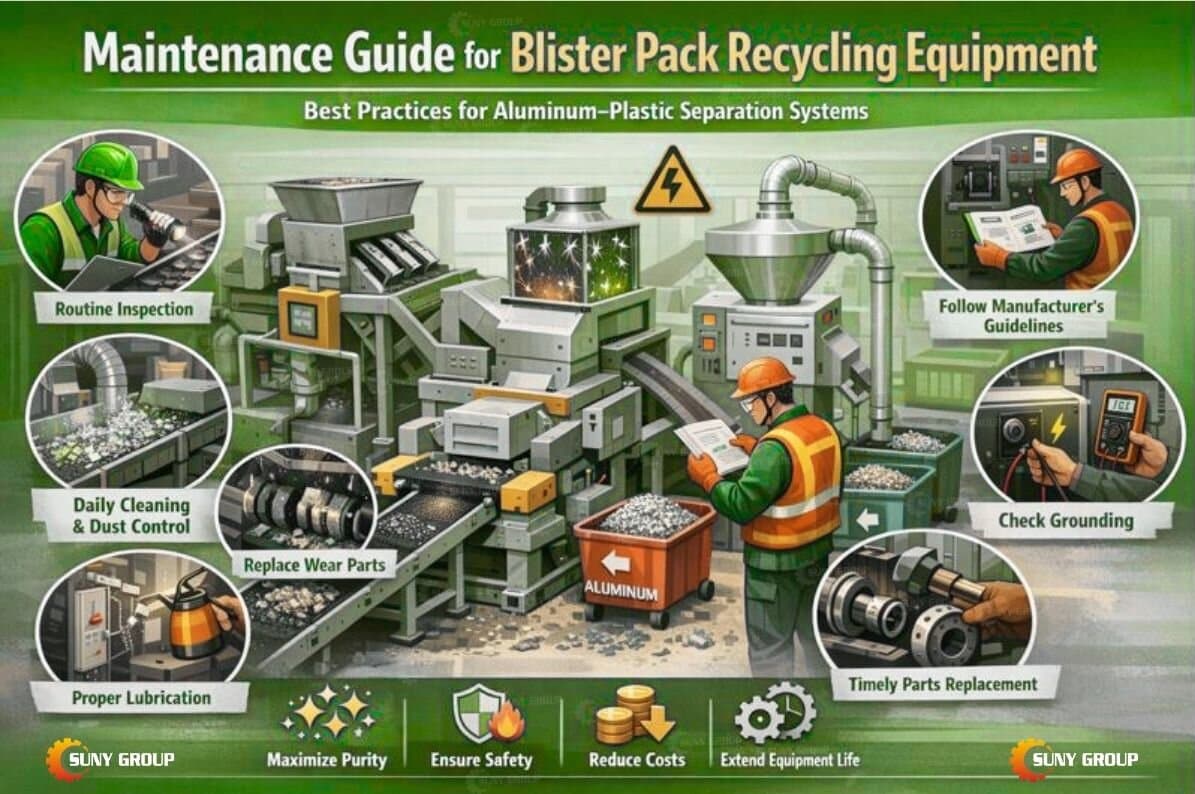

Routine inspection is the foundation of effective equipment maintenance. Regular visual and functional checks help identify early signs of wear, misalignment, or component failure before they escalate into costly downtime. Key areas requiring close attention include conveyor belts, crushing blades, hammers, screens, shafts, bearings, and hydraulic systems. Inspections should be carried out by trained technicians who can accurately diagnose root causes and perform corrective actions using proper tools and original spare parts. Establishing and strictly following a standardized inspection checklist ensures that no critical components are overlooked.

Daily cleaning and dust control are equally critical in blister pack recycling operations. These systems continuously handle mixed materials that can cause clogging, corrosion, and performance degradation if not removed in time. Residues must be cleared from feed hoppers, screen surfaces, electrostatic separator electrodes, and collection boxes. At the same time, the dust extraction system should be checked to ensure stable negative pressure and unobstructed pipelines. Dust accumulation not only reduces separation efficiency but also increases the risk of fire, explosion, and electrostatic malfunction. Consistent cleaning directly supports both safety and product purity.

Proper lubrication is essential for smooth and reliable operation. Insufficient lubrication leads to excessive friction, overheating, and premature wear of moving parts, while over-lubrication can be equally harmful. Maintenance personnel should strictly follow the manufacturer’s recommended lubrication schedule and use approved lubricants. Regular checks of oil levels and grease condition are required for bearings, gearboxes, and shaft couplings, ensuring balanced lubrication and stable mechanical performance.

Timely replacement of wear parts is a key factor in maintaining separation quality. Components such as crusher blades or hammers, mill liners, and screening meshes should be replaced before reaching the end of their service life. Shafts and bearings must also be inspected for signs of fatigue or micro-cracking, as delayed replacement can cause secondary damage to core equipment.

Always adhere to the equipment manufacturer’s maintenance guidelines. These recommendations are designed to optimize performance, operational safety, and system stability. Deviating from specified procedures may result in reduced efficiency, warranty issues, or increased safety risks. Maintenance documentation should be readily accessible, and operators should receive regular technical training.

Common maintenance mistakes to avoid include ignoring fine dust buildup, running worn blades beyond their effective lifespan, skipping grounding inspections of the electrostatic separation system, and overfeeding the machine in pursuit of short-term output gains. These practices inevitably reduce separation purity, increase energy consumption, and accelerate damage to critical components.

A disciplined maintenance strategy ensures that blister pack recycling machines and aluminum–plastic separation systems operate at peak efficiency, delivering high-purity output, lower operating costs, and long-term operational reliability.

👉 Contact Tel: +86 199 0388 6476

👉 Contact Email: sunyrecycle.zack@gmail.com

Welcome to visit SUNY GROUP website. If you want to learn more about our equipments, Contact us Now.

WhatsApp : 86-19903886476

Email : sunyrecycle.zack@gmail.com

Zhengzhou, Henan, China (Mainland)

We specializes in recycling machinery and solid waste treatment solutions, offering aluminum-plastic separation, paper-plastic recycling, diaper recycling, ACP panel stripping and more. We provide customized turnkey systems with raw material testing, installation, training, and strict quality control to ensure stable performance and high recovery rates for long-term customer value.

Provide customized solutions to meet customers' needs for different voltages, capacities, sizes, and appearances

In 2026, we will participate in the following exhibitions and welcome customers to visit us!

Learn More About Our Global Customer Cases