Aluminum continues to gain importance across industries due to its recyclability, high scrap value, and the low energy required for secondary production. Aluminum-plastic composite waste—such as ACP sheets, medical blister packs, and multi-layer packaging—contains valuable aluminum that can be efficiently recovered through fully mechanical processing.

Our aluminum-plastic recycling system is designed to separate aluminum and plastic without chemical treatment. The process combines controlled crushing, precision milling, powder classification, and high-voltage electrostatic separation to produce clean, reusable aluminum and plastic fractions with stable, continuous output. The complete line includes a heavy-duty crusher, turbo-type water-cooled grinding mill, high-efficiency rotary sieve, pulse dust collector, and dual electrostatic separators, all coordinated by a PLC automation system for safe and reliable operation.

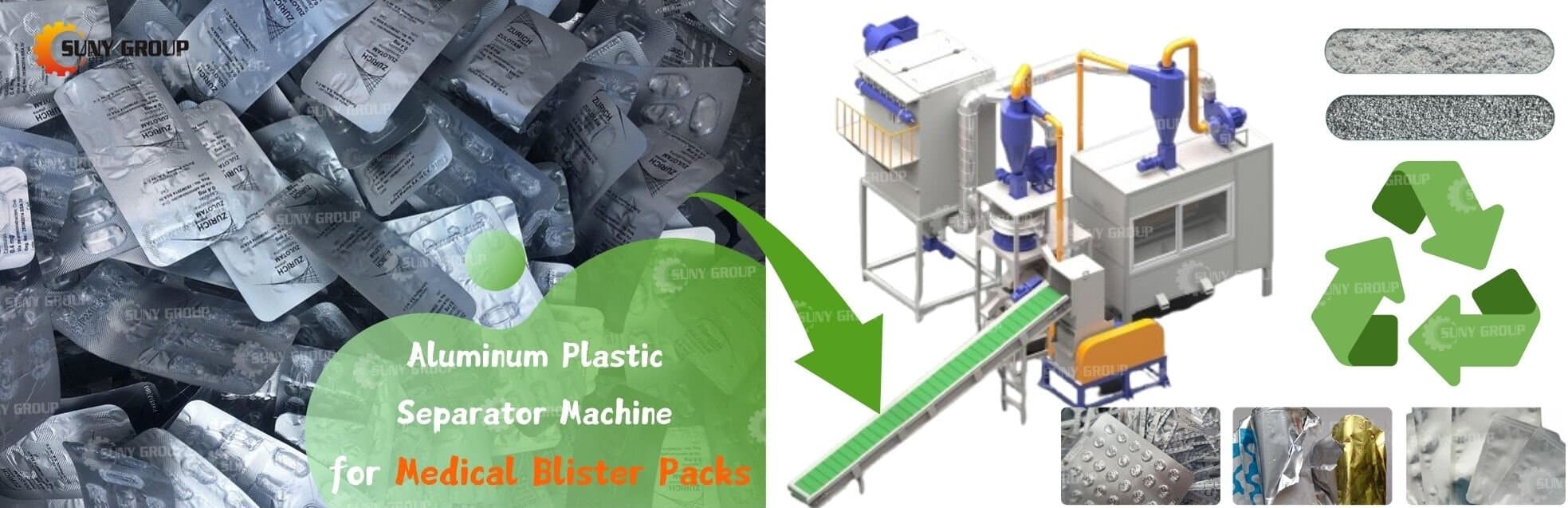

Aluminum Plastic Separator Machine for Medical Blister Packs

Aluminum Plastic Separator Machine for Medical Blister Packs

Recycling begins with size reduction, where waste composite materials are shredded into pieces below 10 mm. This improves feeding efficiency, reduces equipment load, and ensures uniform milling in the next stage. The turbo grinder further refines the material into fine powder within a sealed, negative-pressure environment to minimize dust and maintain consistent particle size. Oversized particles are automatically returned for secondary grinding. The final powder then enters the electrostatic separation system, where aluminum and plastic are separated twice to achieve high-purity recovery—often exceeding 99%.

This technology is widely applied in the recovery of aluminum from medical blister packs. Medical packaging waste typically contains multiple plastic types combined with aluminum foil. Our system’s mechanical separation method ensures high recovery efficiency for complex materials such as PET/PVC, PC/PMMA, PA/PC, and PP/PE, requiring minimal operator intervention. By turning blister waste into reusable raw materials, manufacturers reduce disposal costs and generate new value from previously landfilled waste.

With optimized equipment configuration and tailor-made layouts, we provide complete aluminum-plastic recycling solutions that deliver high purity, stable performance, low operational cost, and strong environmental benefits—helping customers recover valuable aluminum while supporting sustainable production.

👉 Contact Tel: +86 199 0388 6476

👉 Contact Email: sunyrecycle.zack@gmail.com

Welcome to visit SUNY GROUP website. If you want to learn more about our equipments, Contact us Now.

WhatsApp : 86-19903886476

Email : sunyrecycle.zack@gmail.com

Zhengzhou, Henan, China (Mainland)

We specializes in recycling machinery and solid waste treatment solutions, offering aluminum-plastic separation, paper-plastic recycling, diaper recycling, ACP panel stripping and more. We provide customized turnkey systems with raw material testing, installation, training, and strict quality control to ensure stable performance and high recovery rates for long-term customer value.

Provide customized solutions to meet customers' needs for different voltages, capacities, sizes, and appearances

In 2026, we will participate in the following exhibitions and welcome customers to visit us!

Learn More About Our Global Customer Cases