This paper-aluminum-plastic recycling machine can efficiently recover paper fibers, plastic, and aluminum from multi-layer packaging materials (such as Tetra Pak cartons, milk cartons, and blister packaging). Through automated crushing, separation, and dewatering, it produces pulp, plastic, and aluminum.

| Type: | Tetra Pak / Milk Carton Recycling Machine |

| Capacity: | 300-2000 Kg/h |

| Main Application Range: | Tetra Pak and Combibloc beverage cartons, milk and juice boxes |

| Warranty: | 1 Years |

| Brand Name: | SUNY GROUP |

| Certification: | CE Certificate |

Machine Commissioning Video

Raw Materials

The Tetra Pak / Milk Carton Recycling Machine is designed to process a wide range of paper–plastic–aluminum composite materials, including Tetra Pak and Combibloc beverage cartons, milk and juice boxes, pharmaceutical blister packs, cigarette packaging, aluminum-coated paper, and printing or packaging scraps. These high-barrier materials, once difficult to recycle, can now be efficiently separated and reused — turning everyday waste into valuable paper pulp, plastic, and aluminum resources.

With over 20 years of experience in developing and producing paper–plastic recycling equipment, our factory offers complete customized recycling solutions. Every system is professionally designed, thoroughly tested, and supported by a dedicated technical team to ensure optimal performance. We are committed to providing global customers with efficient, eco-friendly, and profitable recycling technologies.

Machine Details Description

The Tetra Pak / Milk Carton Recycling Machine(Paper-Aluminum-Plastic Recycling Machine) is an advanced, fully automated system designed to recover valuable paper fiber, plastic, and aluminum from multi-layer packaging materials such as Tetra Pak cartons, milk boxes, and pharmaceutical blisters. Through an integrated process of shredding, separating, pulping, dewatering, and pressing, it efficiently transforms waste into reusable resources — producing clean paper pulp, recyclable plastic flakes, and recoverable aluminum. Engineered for high efficiency, low energy consumption, and zero secondary pollution, this machine offers a sustainable solution for converting complex packaging waste into valuable raw materials.

| Technical Parameters | |||

| Model | Capacity | Power | Weight |

| ZY-PAP-1000 | 300-2000 (Kg/h) | 60 (Kw) | 5000 (Kg) |

Paper-Aluminum-Plastic Recycling Machine Workflow

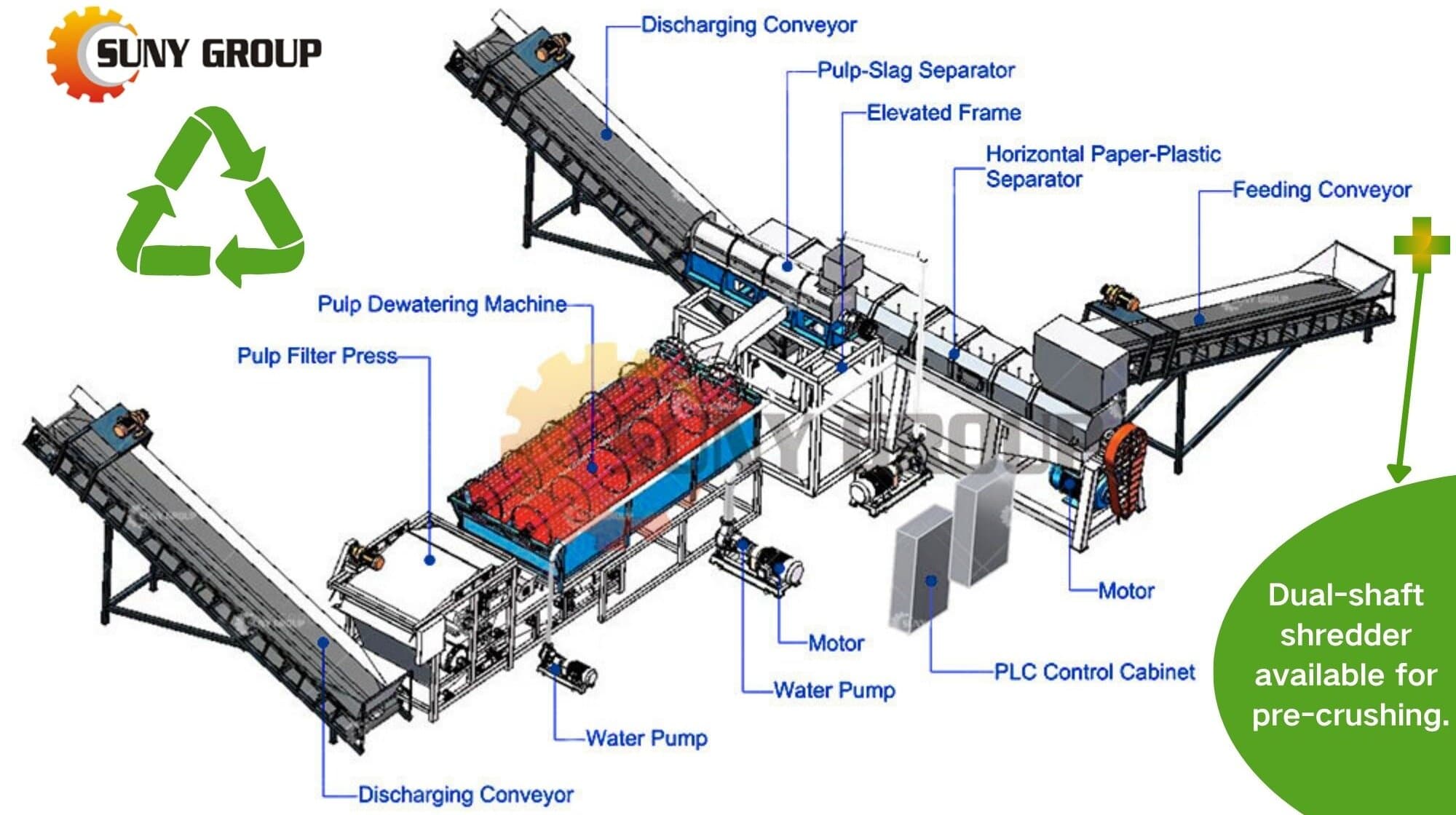

The Paper-Aluminum-Plastic Recycling Machine is a fully automated and efficient system designed for complete material recovery. It includes a Feeding Conveyor, Horizontal Paper-Plastic Separator, Elevated Frame, Pulp-Slag Separator, Pulp Dewatering Machine, Pulp Filter Press, Discharging Conveyor, dual water pumps, and a PLC Control Cabinet, with an optional dual-shaft shredder for pre-crushing. During operation, materials are first fed into the separator for initial paper–plastic separation, followed by impurity and fiber removal in the pulping stage. The refined pulp is then processed through the dewatering machine and filter press to produce high-dryness pulp cakes, while clean plastic flakes are discharged separately. This integrated process ensures stable performance, high separation efficiency, and consistent output of reusable paper and plastic materials.

Machine Performance Showcase

1.Paper Aluminum Separator

It is the main equipment of the production line. The working principle is that the motor drives the spindle to rotate at high speed. The spindle blade drives the material to move from the feeding end to the discharging end. After years of research and development experience and cooperative development by cooperative manufacturers, water mixing and spindle sieve plate friction separation are adopted according to the characteristics of paper-plastic composite and paper-plastic mixture. This paper-plastic separator has passed through many cooperative manufacturers and customers.

2.Pulp-slag Separator

In the pulping of waste paper, because of the different paper quality of waste paper, there is a large amount of slag. This machine can remove light and heavy sundries and decompose small pieces of paper in fibers, without blocking the sieve plate, and hard sundries will not hurt the sieve plate. The factory does not have to stop running for cleaning frequently, and it can also be used as a second pulping machine.It is mainly used for sorting tail pulp after fiber separator and pressure screen; The treated and sorted slurry is directly returned to the fiber separator or the slurry pool in front of the pressure screen for reuse.After sortingThe tailigs do not contain fiber, which meets the emission requirements of environmental protection.

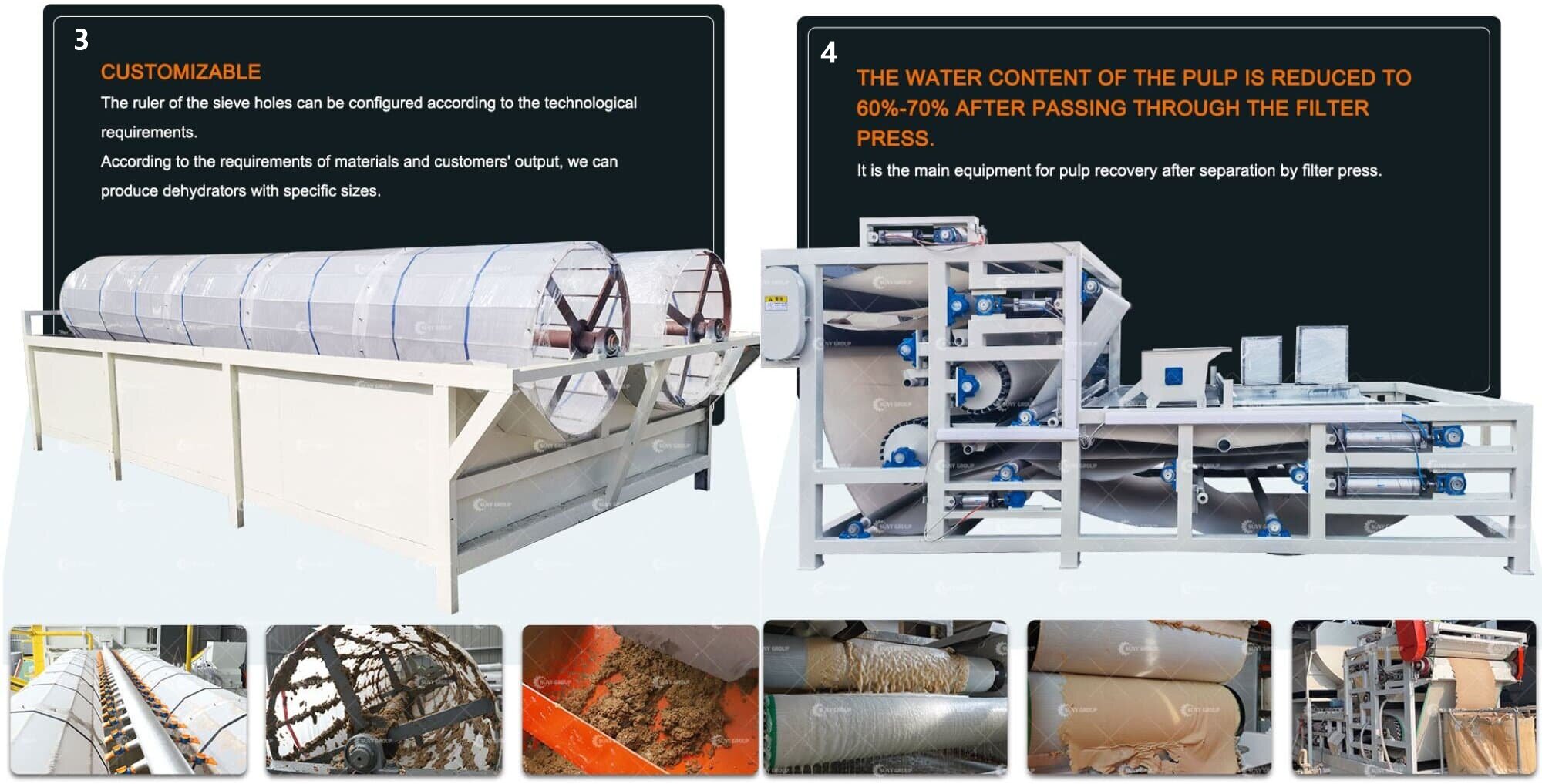

3.Pulp Dewatering Machine

The basic working principle of the pulp dehydato is: the particles rotate to a certain height with the drum, are thrown and fall by gravity, and are filtered through the screen to form a sieve. The roller screen is shaft driven, and the screen is steel wire woven net or high toughness nylon woven net. The ruler of the sieve holes can be configured according to the technological requirements.

4.Pulp Filter Press

Pulp filter press is a mechanical equipment designed for the recycling of pulp separated by paper-plastic separator. The pulp filter press uses the motor to drive the spindle to run and drive the polyester blanket. The pulp is transported to the filter press by the pump and evenly flows onto the polyester blanket. After being driven by the polyester blanket, it is squeezed between two layers of polyester blankets, and then squeezed and compacted by multiple pressing rollers, thus making cardboard for secondary uilization. The filtered clear water can be pumped by a water pump for recycling, thus reducing emissions and saving resources.

Paper-Aluminum-Plastic Recycling Machine Customer Site

We are a professional manufacturer of recycling machinery and equipment, committed to providing complete technical support and excellent customer service. Our experienced engineers offer on-site installation and commissioning to ensure your equipment runs smoothly. We also provide comprehensive technical training, covering operation procedures, maintenance, and common troubleshooting methods. In addition, we offer lifelong technical support, ensuring your production remains efficient and stable. For more information about our machines or to schedule a factory visit (in-person or virtual), please contact our sales team — we’ll help you find the most suitable recycling solution for your needs.

Welcome to visit SUNY GROUP website. If you want to learn more about our equipments, Contact us Now.

WhatsApp : 86-19903886476

Email : sunyrecycle.zack@gmail.com

Zhengzhou, Henan, China (Mainland)

We specializes in recycling machinery and solid waste treatment solutions, offering aluminum-plastic separation, paper-plastic recycling, diaper recycling, ACP panel stripping and more. We provide customized turnkey systems with raw material testing, installation, training, and strict quality control to ensure stable performance and high recovery rates for long-term customer value.

Learn More About Our Global Customer Cases

In 2026, we will participate in the following exhibitions and welcome customers to visit us!

Latest news on machine performance, efficiency, and maintenance tips.