The Expired Baby Diaper Recycling Machine is a specialized recycling system designed for processing expired, defective, or waste baby diapers and sanitary napkins. It effectively separates and recovers SAP (Super Absorbent Polymer), fluff pulp, non-woven fabric, and PE plastic film.

| Type: | Baby Diaper Recycling Plant |

| Capacity: | 500-1000 Kg/h |

| Warranty: | 1 Years |

| Brand Name: | SUNY GROUP |

| Place of Origin: | Hunan, China |

| Certification: | CE Certificate |

Machine Commissioning Video

Machine Details Description

The Baby Diaper Recycling Machine offers an innovative, eco-friendly solution for processing expired or defective baby diapers and sanitary napkins. By efficiently separating SAP, fluff pulp, plastic film, and non-woven fabric, this advanced system transforms waste into valuable reusable materials. Designed for high purity, zero pollution, and strong economic returns, it helps manufacturers reduce waste, recover resources, and contribute to a sustainable circular economy.

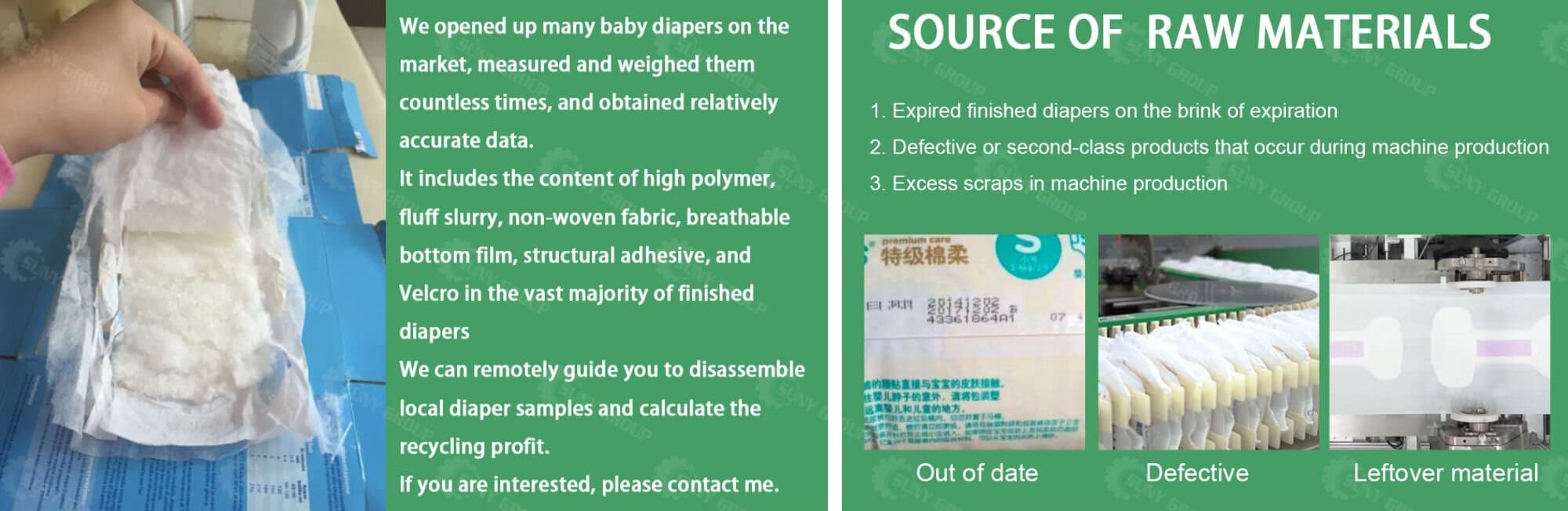

Raw Materials

This recycling line is specially designed to handle expired, defective, or excess baby diapers and sanitary napkins from production lines. It efficiently processes off-grade products, factory scraps, and outdated stock, turning them into reusable materials instead of waste. By converting these hygiene product residues into valuable resources such as SAP, fluff pulp, and plastic film, the system helps manufacturers reduce landfill waste, recover profits, and promote sustainable production across the hygiene and recycling industries.

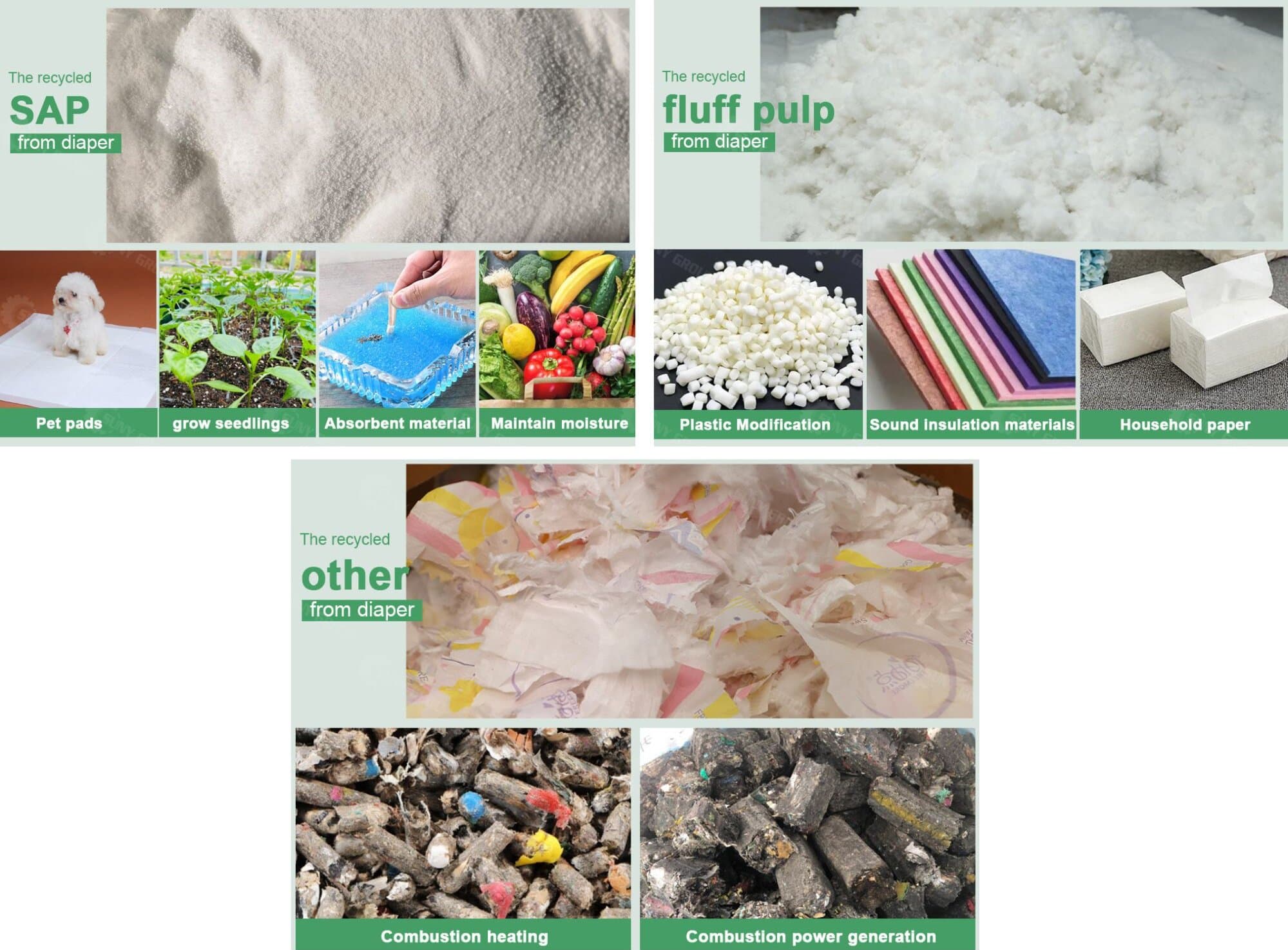

Applications of Recycled Materials

For the health and safety of babies, recycled materials are strictly prohibited from being used to produce new diapers. However, these recovered materials can be repurposed into many valuable and eco-friendly products. The recycled SAP (Super Absorbent Polymer) can be widely used in pet pads, agricultural seedling cultivation, and other moisture-retaining or absorbent applications.

The recycled fluff pulp is ideal for use in household paper, plastic modification, and sound insulation materials. Meanwhile, recovered plastics and non-woven fabrics can be utilized for clean energy generation through combustion or power generation. Through these sustainable applications, waste diapers are effectively turned into renewable resources that create both environmental and economic benefits.

| Technical Parameters | ||||

| Model | Capacity | Power | Weight | Dimension |

| ZY-EBD-1000 | 500 ~ 1000 (Kg/H) | 135 (Kw) | 11800 (Kg) | 14.02 * 7.805 * 6.5 (m) |

Baby Diaper Recycling Machine Process Demonstration

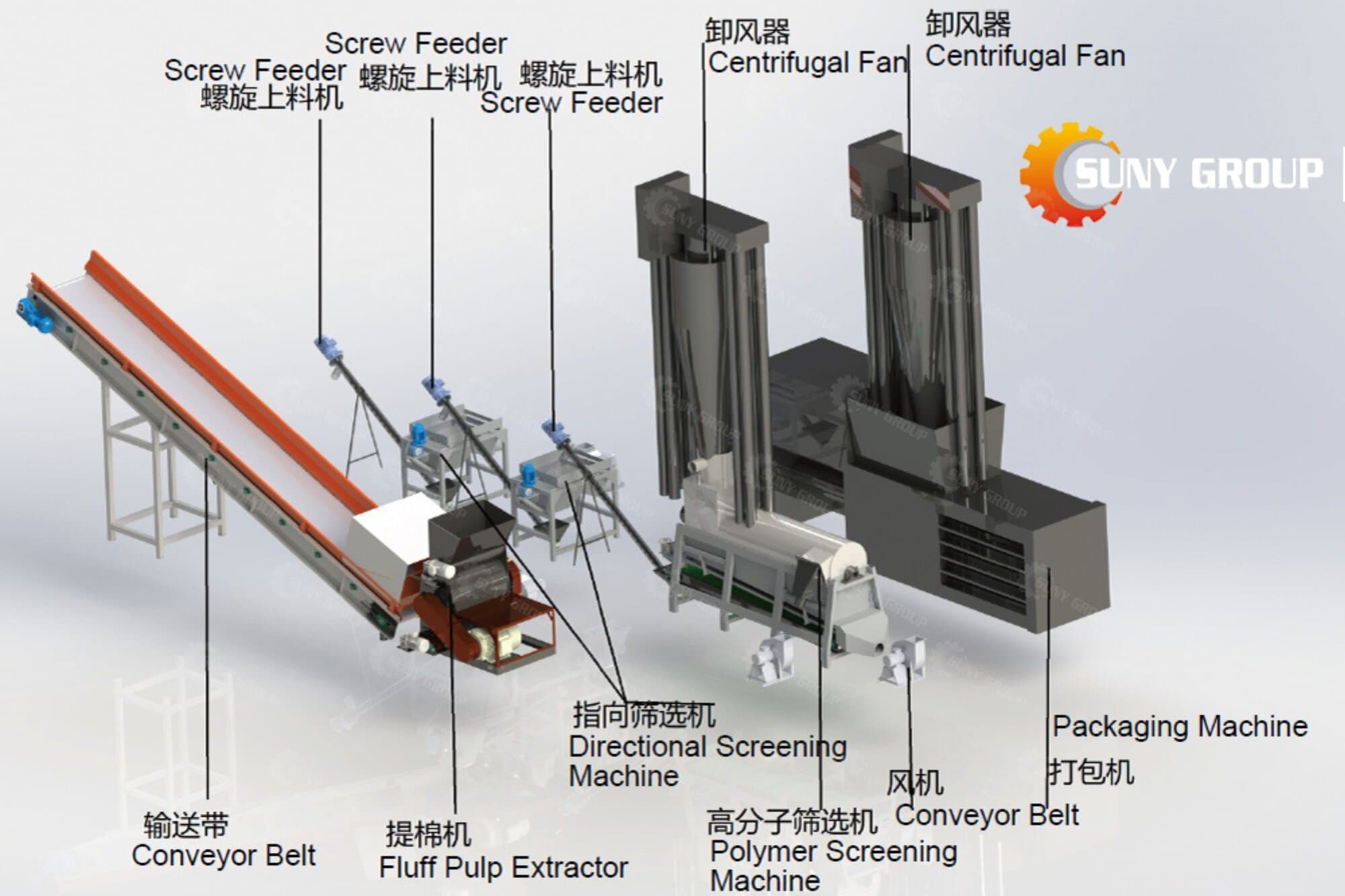

The diaper recycling process transforms waste diapers and sanitary napkins into reusable resources through a fully automated and precisely controlled system. The process begins with the feeding system, where expired or defective products are evenly delivered into the line. Materials are then transported by the screw conveyor and belt conveyor to the soft material cutter for initial size reduction. Next, the directional screening machine separates mixed components such as fluff pulp, SAP (super absorbent polymer), and plastic film.

The fluff pulp extractor uses airflow and mechanical separation to collect clean pulp fibers, while the polymer screening machine precisely screens and recovers SAP with high purity. The fan and cyclone dust collector work together to provide stable airflow, dust removal, and pneumatic conveying, ensuring a clean and efficient operation. Finally, the separated materials are automatically compressed and packed by the baler for easy storage and transportation. From feeding to final collection, every step of the process reflects high efficiency, clean separation, and eco-friendly recycling, turning discarded hygiene products into valuable secondary raw materials.

Machine Performance Showcase

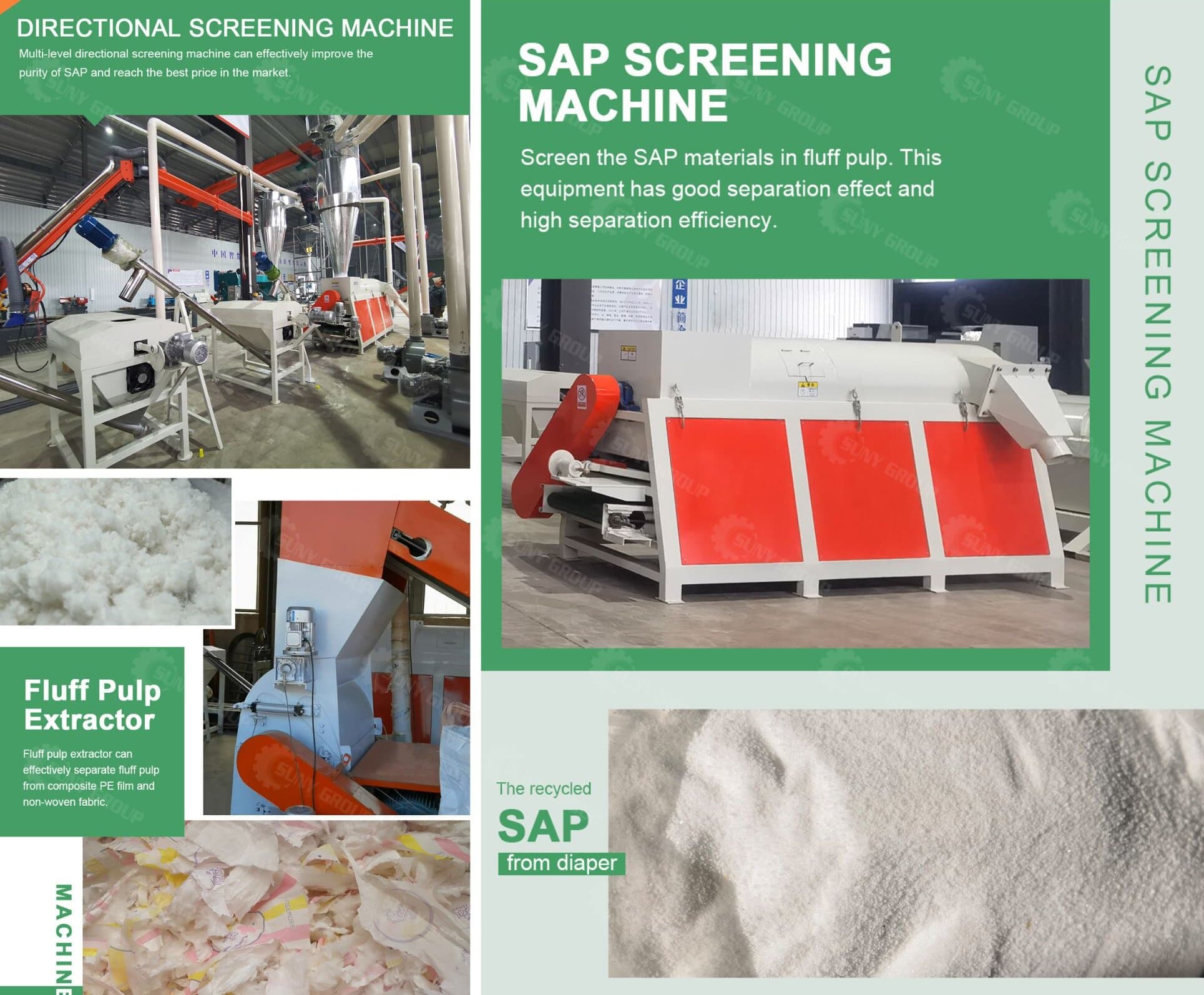

This recycling equipment is specially designed for processing waste materials generated during the production of baby diapers and sanitary napkins. It efficiently separates cotton pulp, plastic film, and super absorbent polymer (SAP) from composite hygiene products. The system integrates a multi-level directional screening machine, a fluff pulp extractor, and an SAP screening unit to ensure high separation accuracy and purity.

Through precise mechanical control, it thoroughly cleans SAP from the pulp and separates non-woven and PE film layers with minimal loss. The result is a highly efficient, low-pollution process that maximizes material recovery and supports both environmental protection and economic sustainability.

Welcome to visit SUNY GROUP website. If you want to learn more about our equipments, Contact us Now.

WhatsApp : 86-19903886476

Email : sunyrecycle.zack@gmail.com

Zhengzhou, Henan, China (Mainland)

We specializes in recycling machinery and solid waste treatment solutions, offering aluminum-plastic separation, paper-plastic recycling, diaper recycling, ACP panel stripping and more. We provide customized turnkey systems with raw material testing, installation, training, and strict quality control to ensure stable performance and high recovery rates for long-term customer value.

Learn More About Our Global Customer Cases

In 2026, we will participate in the following exhibitions and welcome customers to visit us!

Latest news on machine performance, efficiency, and maintenance tips.