The Medical Blister / ACP Recycling Machine is a high-efficiency system designed to separate and recycle aluminum and plastic composites from various laminated materials. It is widely used for processing pharmaceutical blister packs, aluminum plastic films, toothpaste tubes, food packaging bags, and aluminum composite panels (ACP).

| Type: | Medical Blister / Aluminum Composite Panel (ACP) Recycling Plant |

| Capacity: | 300-1000 Kg/h |

| Warranty: | 1 Years |

| Brand Name: | SUNY GROUP |

| Place of Origin: | Hunan, China |

| Certification: | CE Certificate |

Machine Commissioning Video

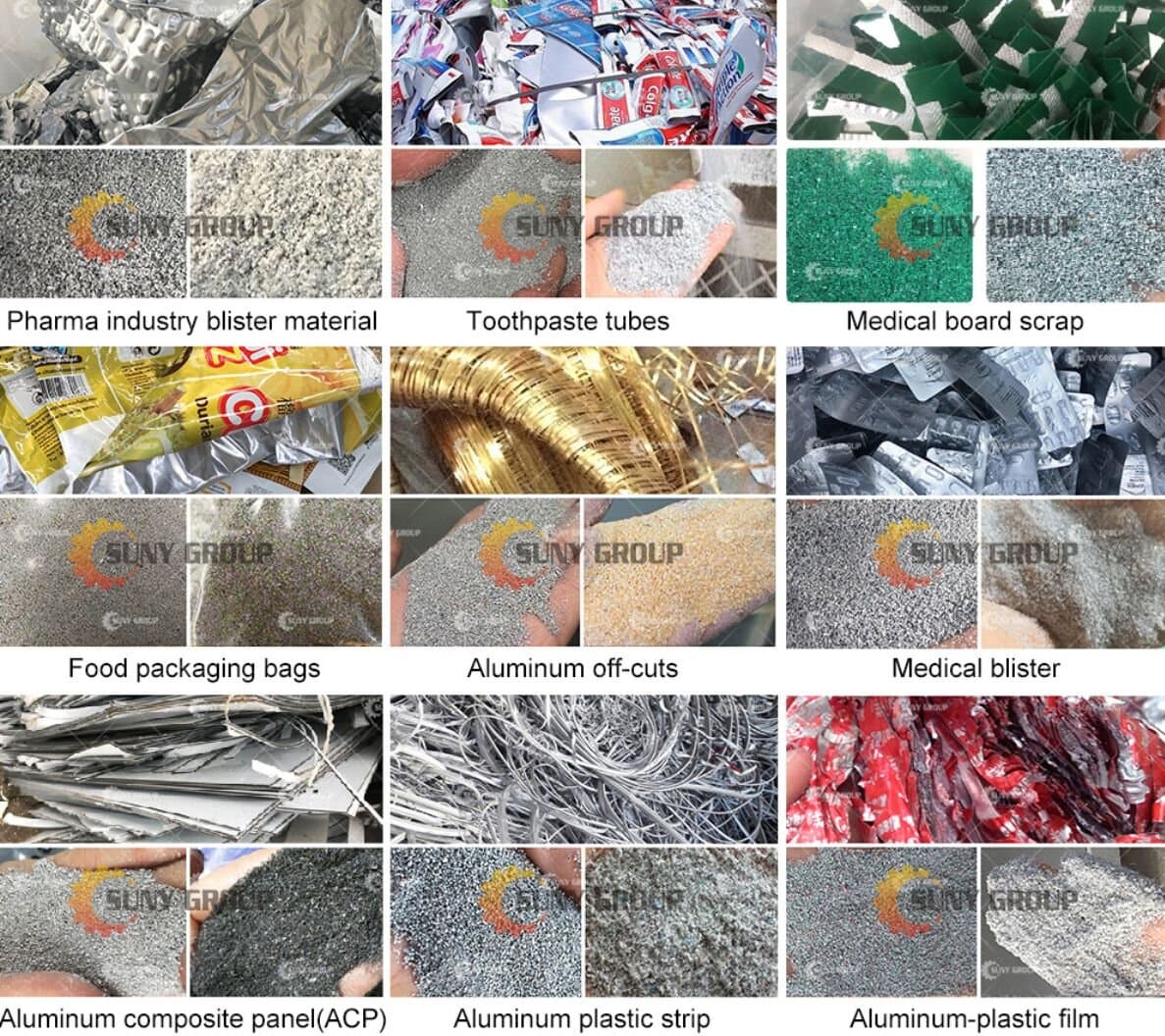

Raw Materials

This recycling line is designed to process a wide variety of aluminum–plastic composite materials commonly found in daily production and packaging industries. It efficiently handles medical blister packs, aluminum plastic films, toothpaste tubes, food packaging bags, aluminum composite panels (ACP), and industrial off-cuts, turning what was once waste into reusable aluminum and plastic resources. Whether from pharmaceutical factories, packaging manufacturers, or ACP production lines, this machine provides a sustainable and profitable solution for recovering valuable materials and reducing environmental impact.

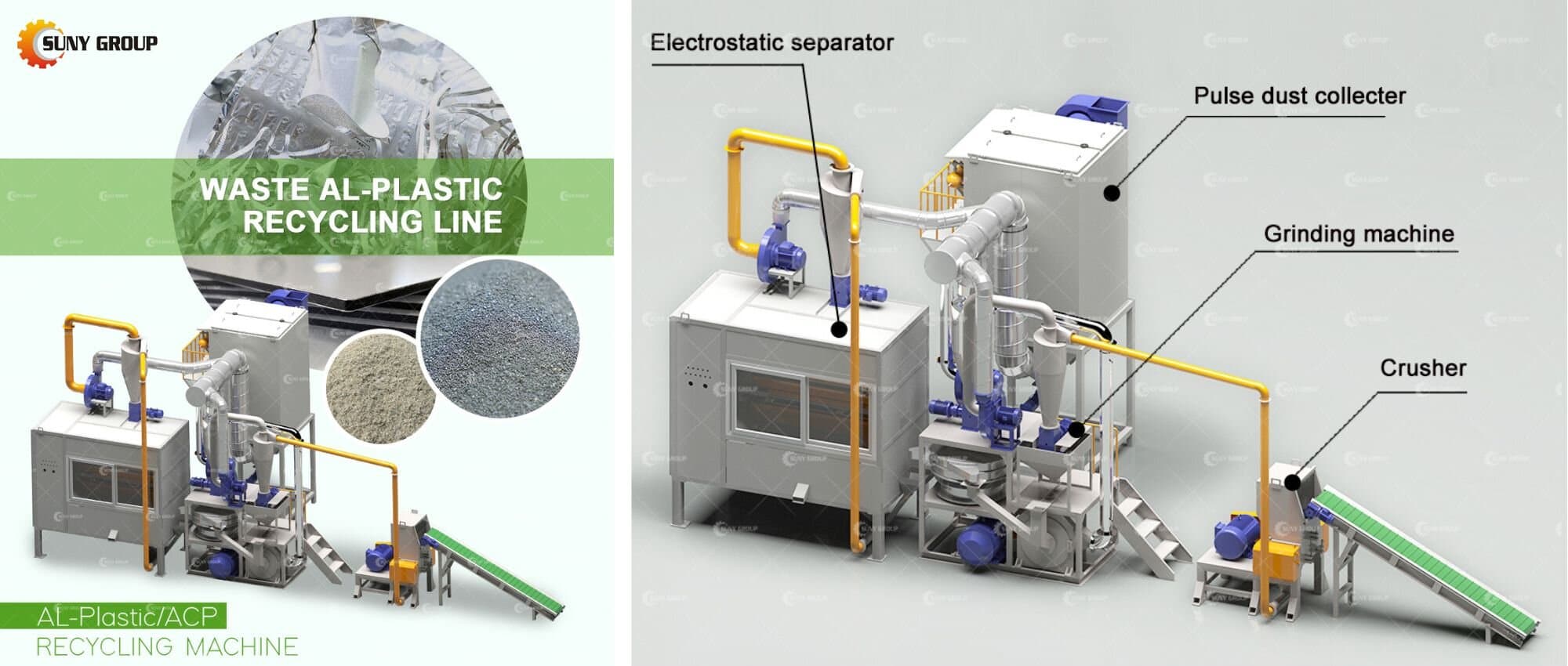

Machine Brief Introduction Details Description

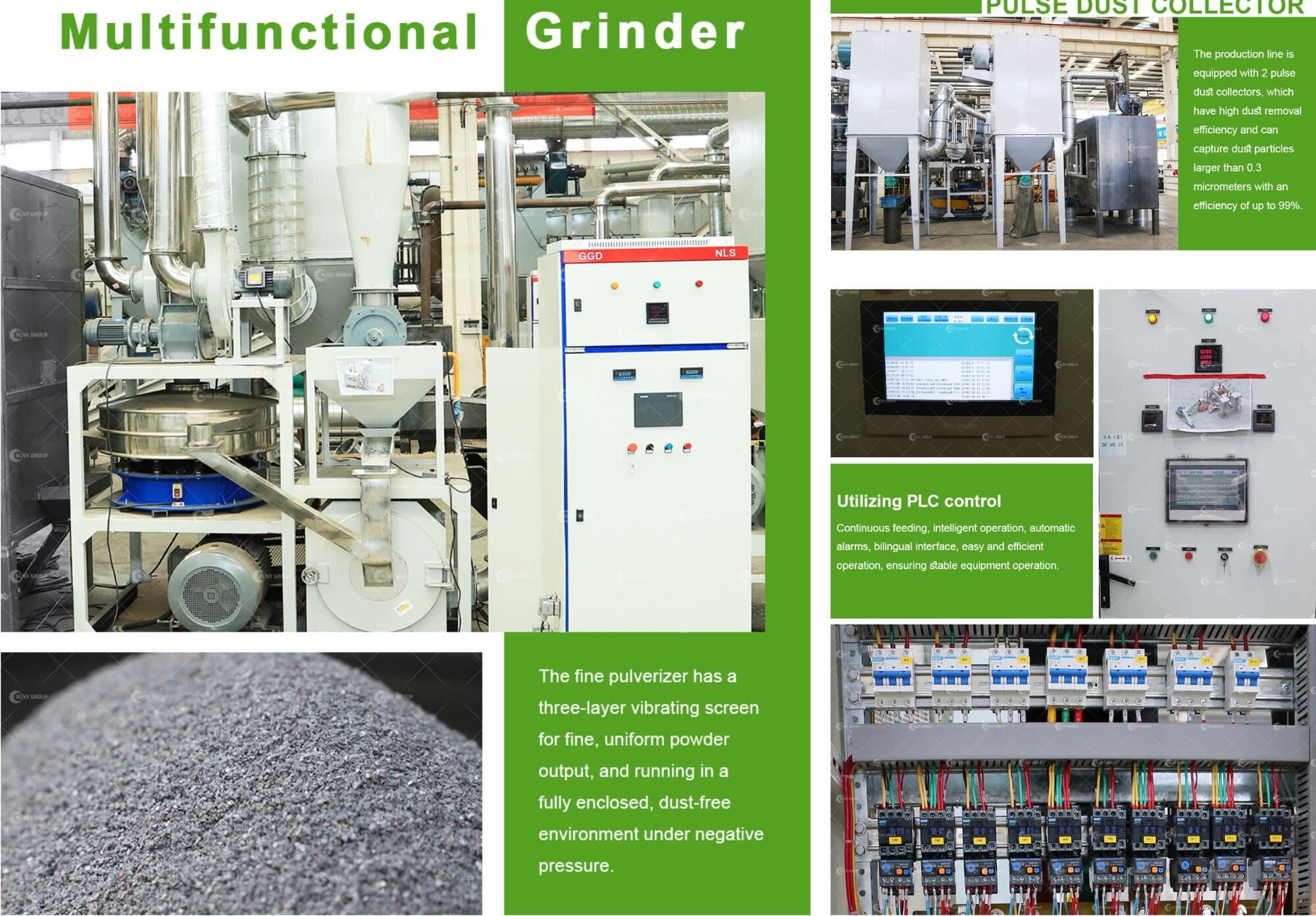

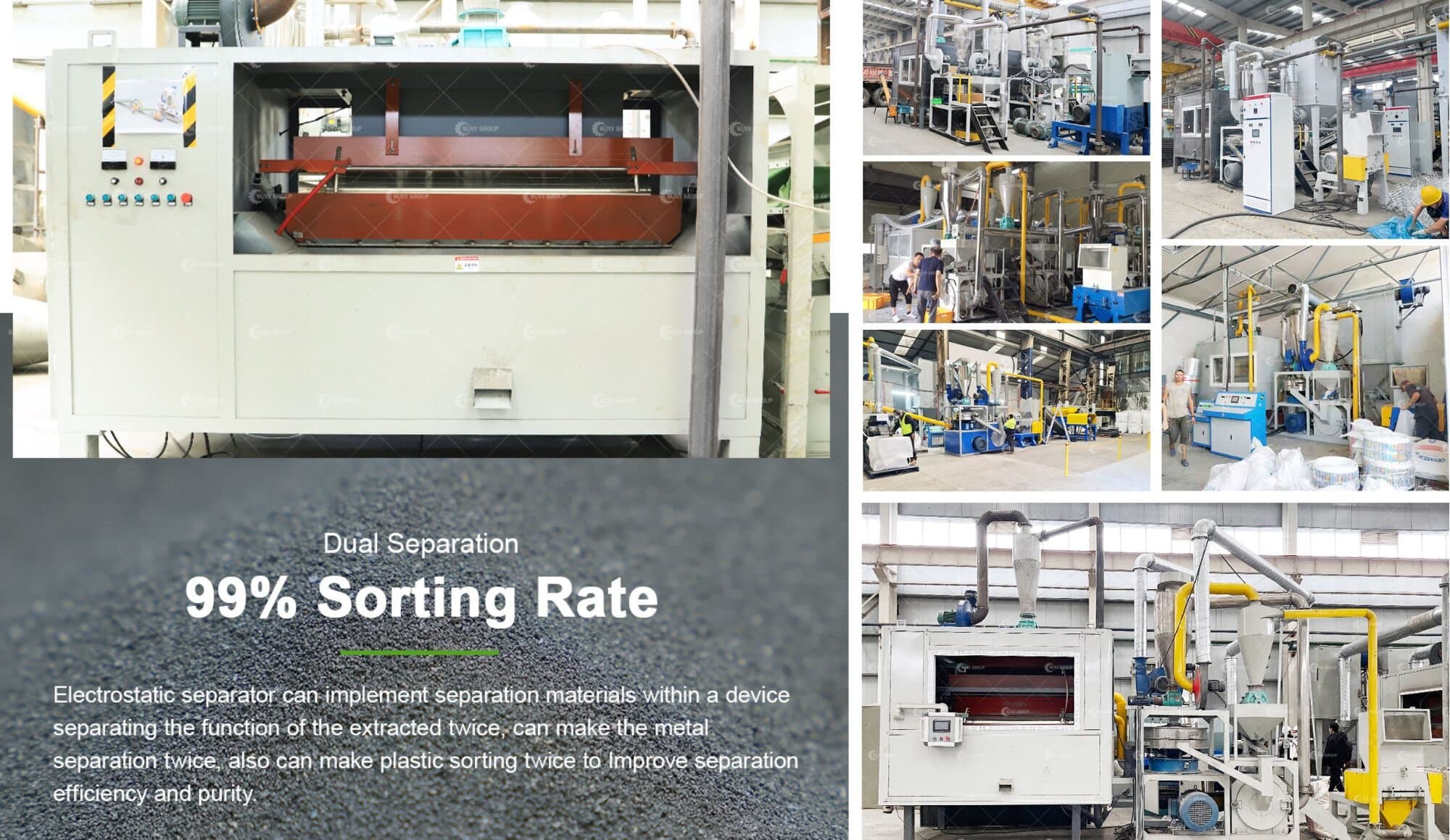

The core system includes a knife crusher for initial size reduction, a turbo-type water-cooled grinder for fine pulverization, a rotary screen for particle classification, and a dual electrostatic separator for high-purity separation of aluminum and plastic. Additional components such as pulse dust collectors, fans, and a PLC control cabinet ensure dust-free operation and intelligent automated control. For higher-capacity operations, an optional single-shaft shredder can be added for pre-shredding larger materials. This comprehensive setup delivers up to 99% separation purity, efficiently turning waste into reusable resources while promoting sustainable and profitable recycling.

| Technical Parameters | |||

| Model | Capacity | Power | Weight |

| ZY-AP-300 | 300 (Kg/H) | 62 (Kw) | 7.5 (T) |

| ZY-AP-500 | 500 (Kg/H) | 98 (Kw) | 12.5 (T) |

| ZY-AP-1000 | 1000 (Kg/H) | 170 (Kw) | 19.5 (T) |

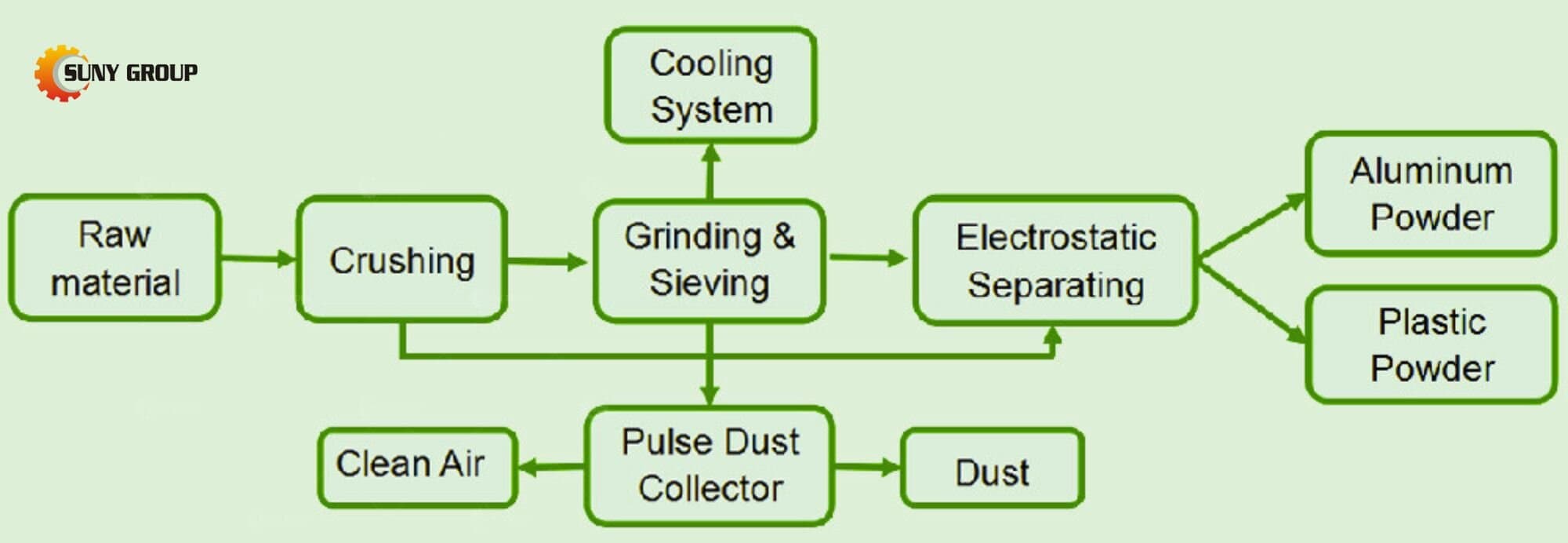

AL Plastic Recycling Machine Workflow

The aluminum and plastic materials firstly crushed by the knife crusher into 10mm pieces, and then grinding by the water cooling turbo type grinding machine into aluminum and plastic fine powders. Then separated by the rotary screen, the big size will back into the grinding machine and the fine powders will into the electrostatic separator, finally the aluminum and plastic would be separated.

Equipment Ddvantages

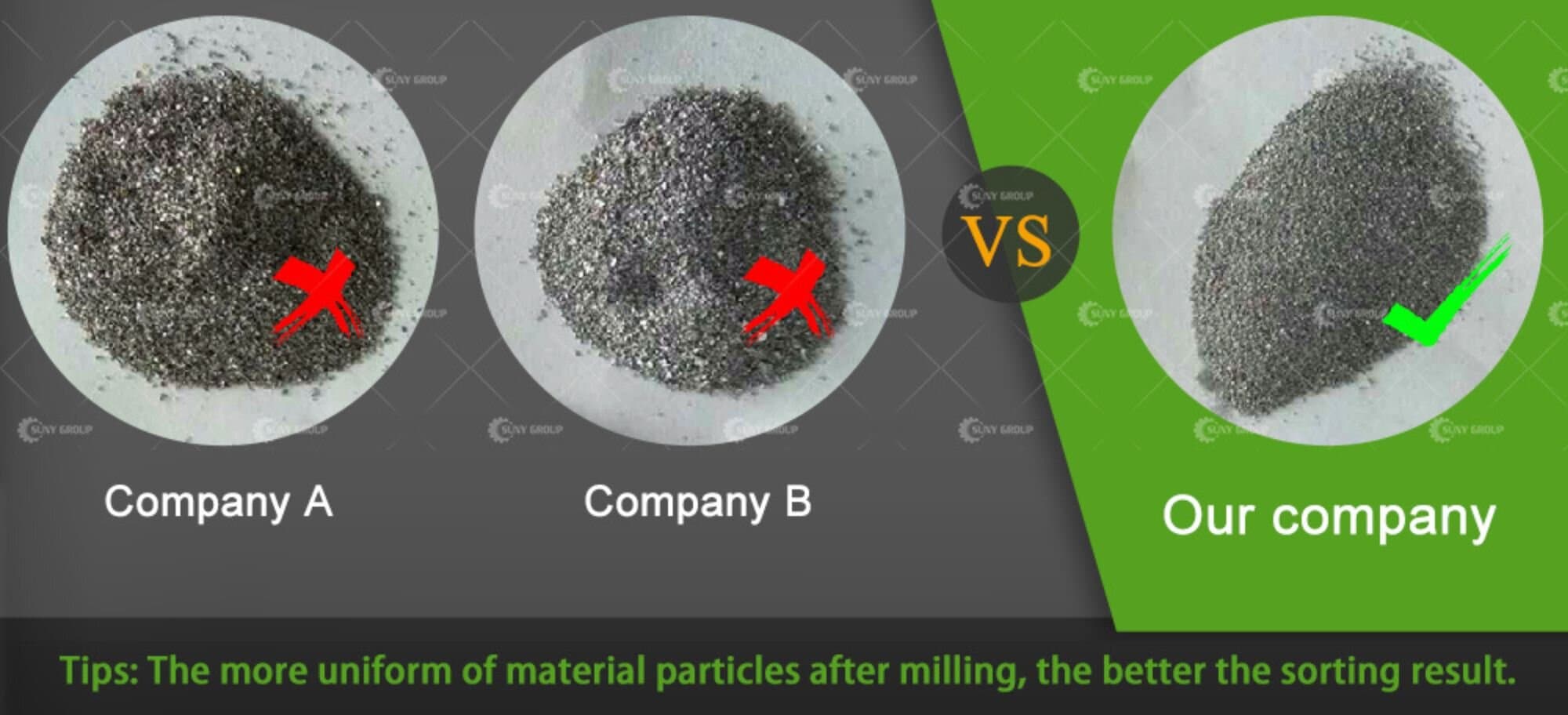

Customer visited our factory for aluminum-plastic separation and recyclingsystem. He visited several suppliers during his tour in China and compared thealumimum powder separated from our system with those of other factores. He isquite satisfied with our equipment.

The machine delivers an electric separation efficiency of up to 99%, producing aluminum and plastic powders that can be directly sold on the market. Equipped with a water-cooled and air-cooled turbo grinding system, it achieves higher grinding efficiency and can handle a wider variety of raw materials. The process is fully green, with no smoke, no wastewater emissions, and zero secondary pollution, ensuring both environmentally friendly operation and high-quality output.

Machine Performance Showcase

The recycling process begins with feeding and pre-shredding, where waste materials are introduced into an optional single-shaft shredder for large-capacity operations. The knife crusher then breaks the materials down to approximately 10–20 mm using a high-hardness main shaft, ensuring maximum impact and efficient size reduction.

Next, the materials undergo fine grinding in a turbo-type water-cooled grinder, producing uniform, fine powder in a fully enclosed, dust-free, negative-pressure environment. Oversized particles are returned to the grinder through a rotary screen, maintaining consistent particle size and preparation for separation.

Finally, the powders enter the dual electrostatic separation system, where aluminum and plastic are separated twice for high-purity recovery, achieving up to 99% separation efficiency. The process is supported by two pulse dust collectors, capturing particles larger than 0.3 μm to ensure safe, clean, and environmentally friendly operation.

AL Plastic Recycling Machine Customer Site

Welcome to visit SUNY GROUP website. If you want to learn more about our equipments, Contact us Now.

WhatsApp : 86-19903886476

Email : sunyrecycle.zack@gmail.com

Zhengzhou, Henan, China (Mainland)

We specializes in recycling machinery and solid waste treatment solutions, offering aluminum-plastic separation, paper-plastic recycling, diaper recycling, ACP panel stripping and more. We provide customized turnkey systems with raw material testing, installation, training, and strict quality control to ensure stable performance and high recovery rates for long-term customer value.

Learn More About Our Global Customer Cases

In 2026, we will participate in the following exhibitions and welcome customers to visit us!

Latest news on machine performance, efficiency, and maintenance tips.