Closing the Loop: How Advanced Physical Separation is Transforming the PE-Coated Paper Crisis.

As the global packaging industry faces a mounting “decommissioning wave” of composite waste, the focus of the recycling sector has shifted from simple disposal to high-value resource recovery. Polyethylene (PE)-coated paper—found in everything from daily coffee cups to complex milk cartons—has long been a “difficult” material for traditional recyclers. The persistent challenge of fiber entrapment and the high cost of chemical separation have often relegated these materials to landfills. However, a breakthrough in physical separation technology is now offering a profitable, sustainable path forward.

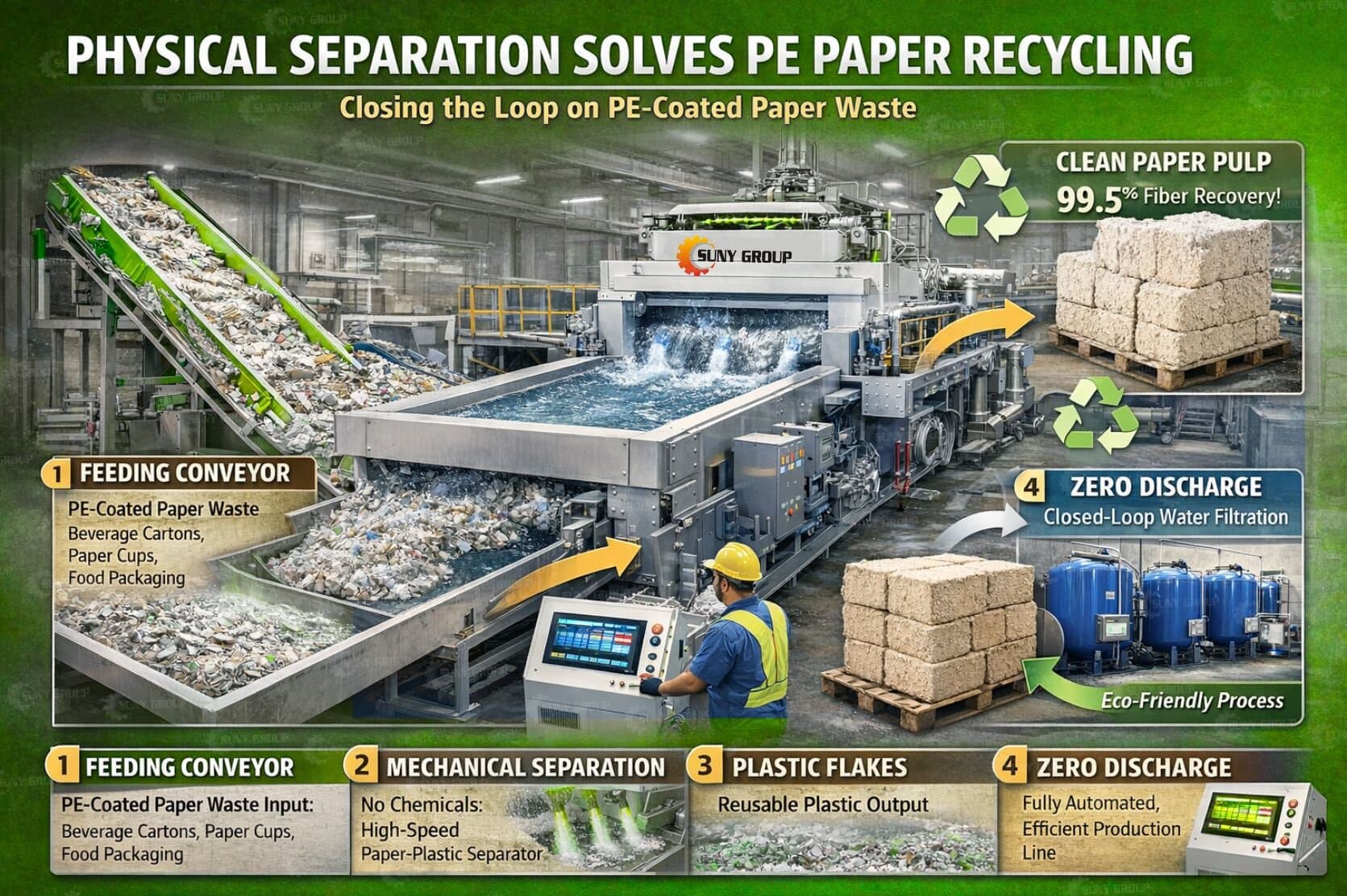

The fundamental problem with recycling PE-coated paper lies in the aggressive bond between organic cellulose and synthetic polymers. Standard hydropulpers often fail to provide enough mechanical friction to strip fibers away from the plastic film, leading to a significant loss of high-value long fibers. Modern industrial solutions, such as the SUNY GROUP Paper-Plastic Recycling Machine , solve this by utilizing a high-speed horizontal separation process. Rather than relying on heat or hazardous chemicals, the system uses multi-stage mechanical agitation and water as a medium to “scrub” the paper clean. This mechanical approach achieves a remarkable fiber recovery rate, ensuring that up to 99.5% of paper fibers are captured as high-purity pulp.

Operational efficiency has also been a major hurdle for recyclers, with “stickies” and plastic residue frequently clogging filtration screens and causing expensive downtime. To address this, the latest generation of recycling equipment integrates PLC-controlled automation with high-consistency pulping. Systems now feature automatic “detrashing” mechanisms that remove plastic ribbons and slag without pausing the production line. This continuous operation not only lowers labor costs but also maintains a steady output of “pulp cakes”—compressed, dry fiber blocks that are far more valuable and easier to transport than traditional wet slurry.

Environmental compliance remains a non-negotiable factor in 2026. As stricter regulations—such as those requiring post-consumer recycled content in North America and the EU—come into effect, the “secondary pollution” generated by chemical recycling methods is becoming a liability. Physical separation systems eliminate this risk entirely. By incorporating a closed-loop water filtration system, modern recycling lines achieve zero-discharge operations, recycling the water used in the separation process. This not only meets stringent environmental standards but also dramatically reduces energy consumption and operational risks associated with high-pressure or high-heat systems.

Ultimately, the choice of a recycling solution is about more than the initial price tag; it is an investment in output purity and long-term reliability. By transforming what was once considered unrecyclable waste into two distinct, high-purity streams—clean paper pulp and reusable plastic flakes—recyclers can finally unlock the full economic potential of the circular economy. For those interested in seeing these innovations firsthand, factory visits and virtual demonstrations are now available to showcase the future of composite material recovery.

👉 Contact Tel: +86 199 0388 6476

👉 Contact Email: sunyrecycle.zack@gmail.com

Welcome to visit SUNY GROUP website. If you want to learn more about our equipments, Contact us Now.

WhatsApp : 86-19903886476

Email : sunyrecycle.zack@gmail.com

Zhengzhou, Henan, China (Mainland)

We specializes in recycling machinery and solid waste treatment solutions, offering aluminum-plastic separation, paper-plastic recycling, diaper recycling, ACP panel stripping and more. We provide customized turnkey systems with raw material testing, installation, training, and strict quality control to ensure stable performance and high recovery rates for long-term customer value.

Provide customized solutions to meet customers' needs for different voltages, capacities, sizes, and appearances

In 2025, we will participate in the following exhibitions and welcome customers to visit us!

.png)

.png)

.png)

.png)

Learn More About Our Global Customer Cases