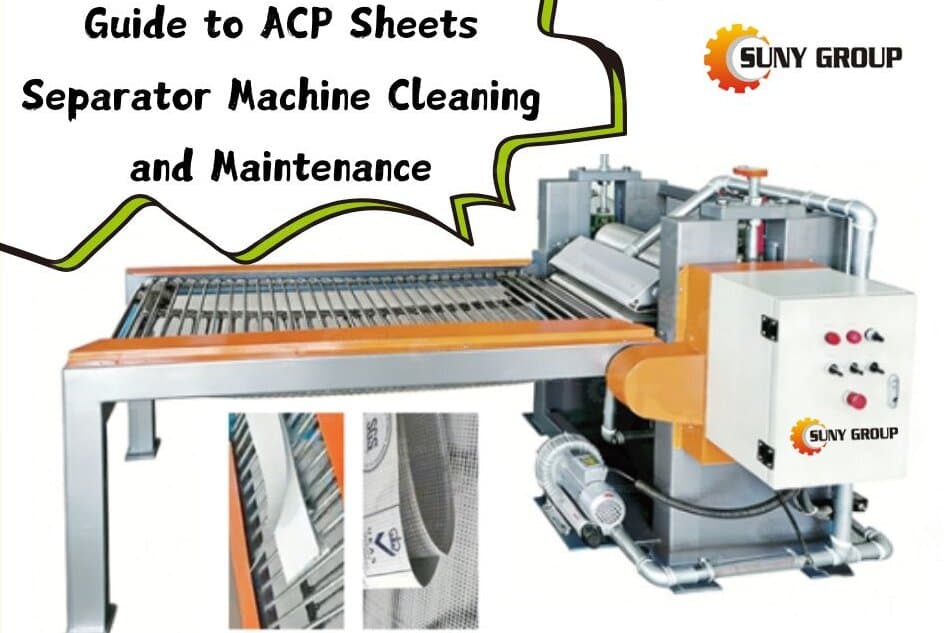

The ACP Sheets Separator Machine operates by heating the ACP panels to separate the aluminum layers from the plastic core, ensuring the recovery of intact materials. This controlled separation process ensures high purity of output while maintaining low energy consumption. With its compact structure and user-friendly design, the ACP separator delivers efficient recycling results with minimal operational complexity. Designed specifically for recycling ACP sheets, this machine enables recyclers to recover aluminum and plastic cleanly with low investment, easy operation, and stable performance, making it an ideal choice for small- to medium-sized recycling plants.

Proper daily operation and regular maintenance are essential to ensure long-term performance and safety. During the first week of operation, belt tension should be checked daily and inspected at least twice a week thereafter. Any looseness must be adjusted promptly to maintain stable transmission. All fasteners should be inspected regularly to ensure they remain secure during continuous operation.

Bearings and other moving components require consistent lubrication to reduce wear and extend service life. Lubrication conditions should be checked frequently, and grease applied according to recommended operating hours. Electrical systems must also be inspected on a regular basis, including cable insulation, terminal connections, and explosion-proof surfaces. Damaged cables should be replaced immediately, and loose wiring securely tightened to prevent electrical faults.

Whether the ACP Separator Machine is powered by electricity or natural gas, routine safety checks are critical to avoid potential accidents. Before any maintenance work, the power supply must be completely disconnected. Maintenance personnel should keep the control panel keys with them and clearly display warning signs indicating that the machine is under service and must not be started. Welding operations on pipelines or machine housings are strictly prohibited while the equipment is running.

With proper use and standardized maintenance, the ACP Separator Machine delivers stable operation, long service life, and consistent recycling efficiency. It is a practical, low-risk, and high-return solution for ACP recycling, helping customers turn ACP waste into valuable recycled materials while maintaining safe and reliable production.

👉 Contact Tel: +86 199 0388 6476

👉 Contact Email: sunyrecycle.zack@gmail.com

Welcome to visit SUNY GROUP website. If you want to learn more about our equipments, Contact us Now.

WhatsApp : 86-19903886476

Email : sunyrecycle.zack@gmail.com

Zhengzhou, Henan, China (Mainland)

We specializes in recycling machinery and solid waste treatment solutions, offering aluminum-plastic separation, paper-plastic recycling, diaper recycling, ACP panel stripping and more. We provide customized turnkey systems with raw material testing, installation, training, and strict quality control to ensure stable performance and high recovery rates for long-term customer value.

Provide customized solutions to meet customers' needs for different voltages, capacities, sizes, and appearances

In 2026, we will participate in the following exhibitions and welcome customers to visit us!

Learn More About Our Global Customer Cases